Manufacturing Day celebrates the achievements of American manufacturers. This celebration takes place on the first Friday of October. It is also a chance to inspire the next generation of manufacturing workers to explore careers in this industry.

Manufacturing Day is celebrated by many organizations. These events can be organized by schools, corporations, and other organizations. Some events may include factory tours and presentations. Other events may include virtual content about local manufacturing companies. Many of these events provide hands-on opportunities for students.

Manufacturers are an essential part of the economy. Each dollar spent in manufacturing generates $2.79 for the economy. It is also important to note that manufacturing is an industry that requires a skilled workforce. Small manufacturers spend 2.5 times as much as large manufacturers.

A number of federal agencies have supported Manufacturing Day, including the Department of Education, the Advanced Manufacturing Office, and the National Association of Manufacturers. Manufacturers have the opportunity to network with their local communities and schools on this special day. These agencies provide support and resources for planning events. They also support official proclamations and factory tours.

Some companies organize special seminars to inspire youth to pursue a career in manufacturing. The Manufacturing Institute is a National Association of Manufacturers partner and supports these efforts. The Institute offers resources to assist manufacturers in addressing industry challenges and building stronger communities. The Institute also supports women and veterans in manufacturing.

The Biden/Harris administration is trying to revitalize the manufacturing industry. They plan to focus on strengthening supply chains and investing R&D.

AIM's 3D Virtual Reality Headsets provide students with the opportunity to learn advanced manufacturing careers. AIM will work with local schools to transport students to factories that produce products. Students will be able to see the facilities from a virtual perspective and learn how they produce high-quality products. Students will have the opportunity to participate in virtual panels.

Manufacturing Day events are not the only thing that are celebrated. The National Strategy for Advanced Manufacturing is also a big deal. The Strategy encourages all manufacturers to be involved in educational opportunities and training programs that are beneficial to the local economy. Manufacturing companies can also host job fairs for people looking to find work in the manufacturing industry.

The Manufacturing Institute hosts events that allow students to discover more about the manufacturing industry. This event is also designed to help promote the benefits of diversity and inclusion in manufacturing. Some events also feature testimonials from people who work in manufacturing.

The National Association of Manufacturers (Factorators and Manufacturers Association) and the National Retail Federation (National Retail Federation) will offer many educational opportunities and demonstrate the importance of manufactured goods. These events offer students a unique opportunity to learn about the economic importance of manufacturing and to explore the various career options available in this field.

FAQ

What is the difference between a production planner and a project manager?

The primary difference between a producer planner and a manager of a project is that the manager usually plans and organizes the whole project, while a production planner is only involved in the planning stage.

What is the difference in Production Planning and Scheduling, you ask?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. Forecasting demand is one way to do this.

Scheduling involves the assignment of dates and times to tasks in order to complete them within the timeframe.

How can manufacturing avoid production bottlenecks

Avoiding production bottlenecks is as simple as keeping all processes running smoothly, from the time an order is received until the product ships.

This includes planning for both capacity requirements and quality control measures.

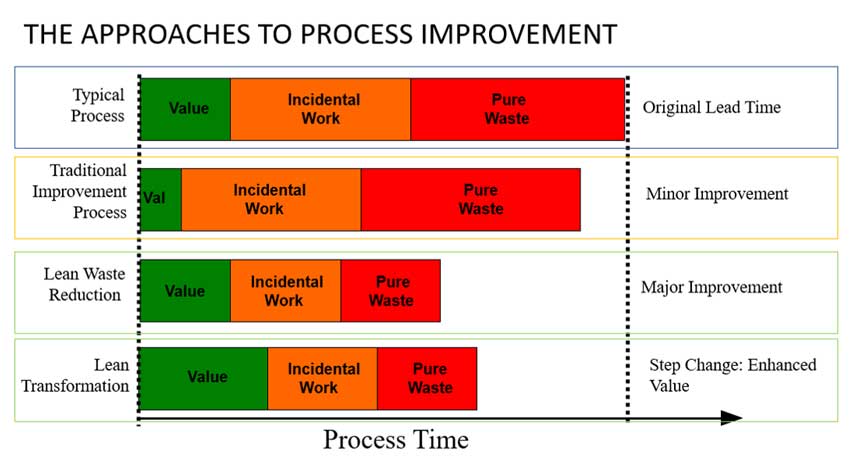

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma is a management system used to improve quality and reduce waste in every aspect of your organization.

It emphasizes consistency and eliminating variance in your work.

Is automation important in manufacturing?

Not only are service providers and manufacturers important, but so is automation. It allows them to offer services faster and more efficiently. It reduces human errors and improves productivity, which in turn helps them lower their costs.

What are manufacturing & logistics?

Manufacturing is the process of creating goods from raw materials by using machines and processes. Logistics manages all aspects of the supply chain, including procurement, production planning and distribution, inventory control, transportation, customer service, and transport. Manufacturing and logistics can often be grouped together to describe a larger term that covers both the creation of products, and the delivery of them to customers.

Can some manufacturing processes be automated?

Yes! Yes! Automation has existed since ancient times. The Egyptians created the wheel thousands years ago. Nowadays, we use robots for assembly lines.

Robotics is used in many manufacturing processes today. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that make products

There are many other examples of how manufacturing could benefit from automation. For instance, 3D printing allows us make custom products and not have to wait for months or even weeks to get them made.

Statistics

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

External Links

How To

How to Use the Just-In-Time Method in Production

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. This is where you have the right resources at the right time. This means that your only pay for the resources you actually use. Frederick Taylor first coined this term while working in the early 1900s as a foreman. He noticed that workers were often paid overtime when they had to work late. He realized that workers should have enough time to complete their jobs before they begin work. This would help increase productivity.

JIT is an acronym that means you need to plan ahead so you don’t waste your money. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You'll be prepared to handle any potential problems if you know in advance. This will prevent you from spending extra money on unnecessary things.

There are several types of JIT techniques:

-

Demand-driven: This type of JIT allows you to order the parts/materials required for your project on a regular basis. This will allow for you to track the material that you have left after using it. You'll also be able to estimate how long it will take to produce more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows you predict the amount you can expect to sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based: This is the most common form of JIT. You assign certain resources based off demand. For example, if there is a lot of work coming in, you will have more people assigned to them. If you don't receive many orders, then you'll assign fewer employees to handle the load.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing only on how much each employee is costing, you should focus on how long it takes to complete your project.

-

Quality-based JIT: This is another variation of resource based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT : This is the newest type of JIT. In this case, you're not concerned with how well the products perform or whether they meet customer expectations. Instead, you're focused on how much value you add to the market.

-

Stock-based: This is an inventory-based method that focuses on the actual number of items being produced at any given time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-intime planning (JIT), is a combination JIT/sales chain management. It's the process of scheduling delivery of components immediately after they are ordered. It's important as it reduces leadtimes and increases throughput.