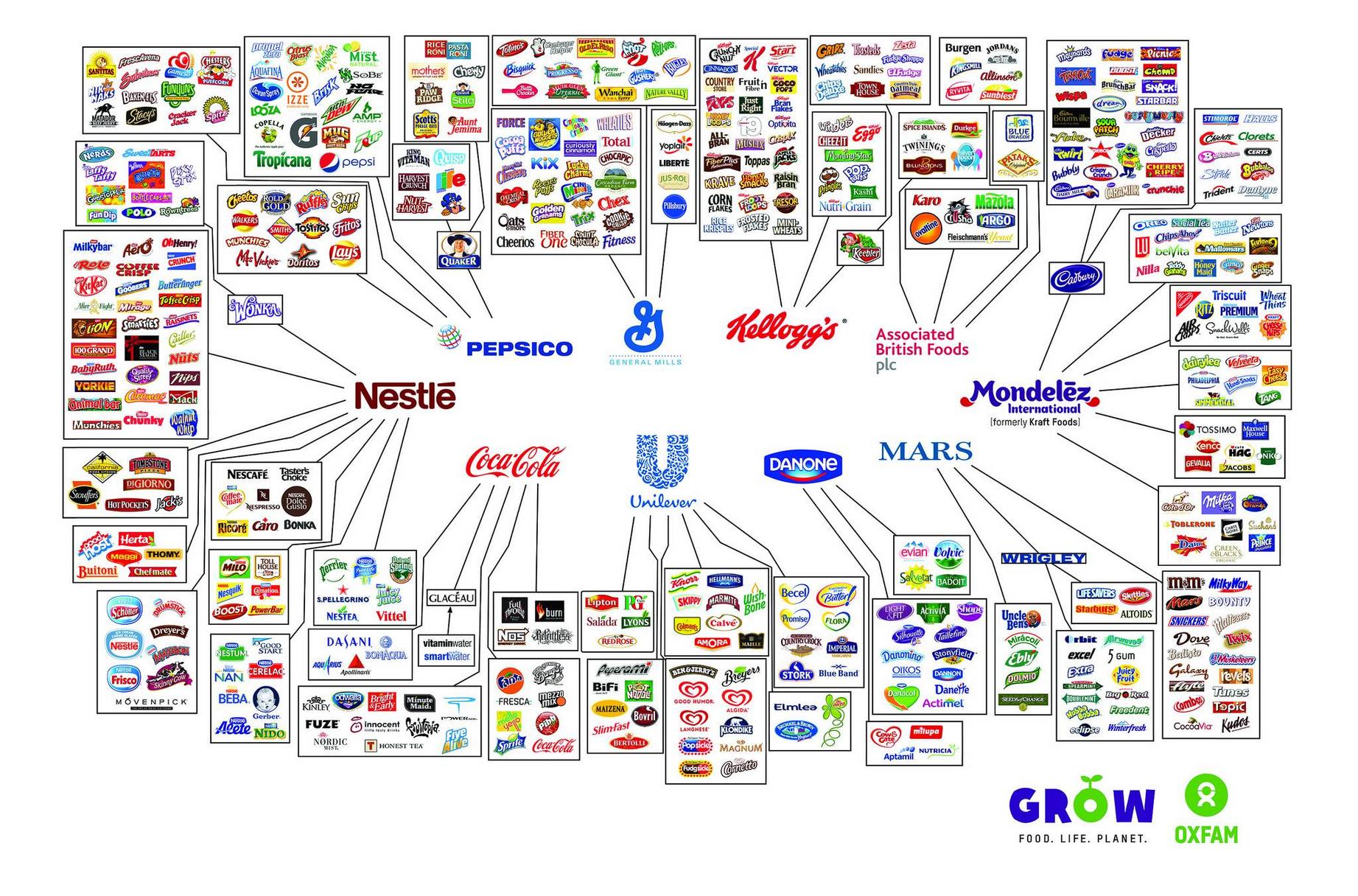

Three basic sectors are the basis of classical economics. Manufacturing, services, and financial activities can be classified into these three categories. The characteristics and risk factors that go into a business' classification are important. Below, you will learn more about each of the three sectors. Below is a brief overview about the types of businesses found in each sector. If you are interested, you can explore the information further. You should remember that these categories can't be considered mutually exclusive.

Economic activity

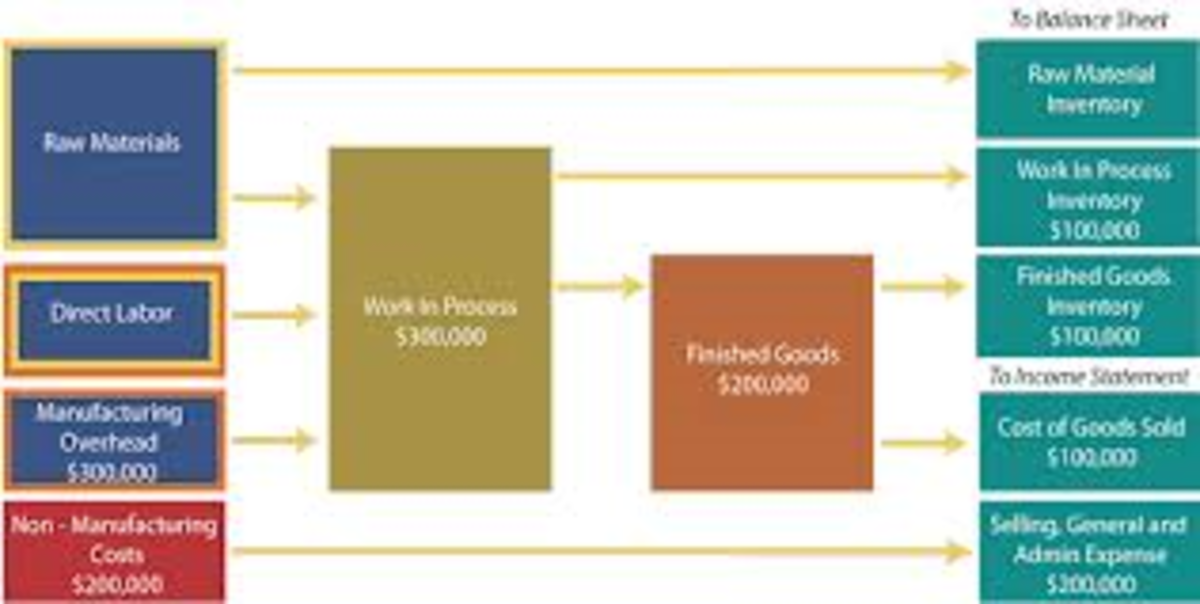

Factors used in production, inputs and outputs determine the economic activity of a country or nation. A region's ability to produce a particular product or service determines its economic activity. There are two types if economic activity. Primary economic activities produce goods and services that satisfy human needs. While secondary economic activities add value by combining raw materials into a better product, they are not as valuable. Examples of secondary economic activities are manufacturing and processing.

Classification of businesses

Business classification is the process by which businesses are divided into groups based upon the activities they engage in. There are two main categories: primary and secondary. Primary businesses are those that use natural resources to extract them and then exchange them. The second type of businesses process and convert raw materials into consumer-ready products. There are numerous differences between these two types of businesses. Here are some major differences between both types. This article can help you choose the right type of business for your company.

Characteristics

Following discussion will discuss the differences in the primary, second, and third sectors. It will also focus on how each sector impacts the economy. First, let's define sectors. Each sector is an economic entity that responds differently to different factors. These conditions can be repeated (e.g. business cycles) or one-off events (e.g. technological improvements). These characteristics can help identify the most viable sector and determine their relative importance to an economy.

Risks

Industry risk is the variation in performance across industries and their companies. It is measured by the variation in return on equity and profitability. Depending on the industry, this may also reflect the performance of stock markets. One example is that a company manufacturing steel is considered high-risk due to the risk of major earthquakes occurring in the region. An analysis of these risks can help investors identify volatile sectors.

Investments

Although many investors prefer to invest in companies, it is possible to invest in sectors. These sectors are less risky and can be found in mutual fund and exchange-traded money. In addition, sector investing is becoming a popular investment strategy today. This article will discuss how sector investing can help you find the right investments. For more information, please read on. And don't forget to check out our free resource section for more information.

FAQ

Are there ways to automate parts of manufacturing?

Yes! Yes. The Egyptians invent the wheel thousands of year ago. To help us build assembly lines, we now have robots.

Robotics is used in many manufacturing processes today. These include:

-

Assembly line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots create products

Automation could also be used to improve manufacturing. For instance, 3D printing allows us make custom products and not have to wait for months or even weeks to get them made.

How can I find out more about manufacturing?

Hands-on experience is the best way to learn more about manufacturing. You can read books, or watch instructional videos if you don't have the opportunity to do so.

What's the difference between Production Planning & Scheduling?

Production Planning (PP), also known as forecasting and identifying production capacities, is the process that determines what product needs to be produced at any particular time. Forecasting demand is one way to do this.

Scheduling is the process that assigns dates to tasks so they can get completed within a given timeframe.

What is the responsibility for a logistics manager

A logistics manager ensures that all goods are delivered on time and without damage. This is done using his/her knowledge of the company's products. He/she should make sure that enough stock is on hand to meet the demands.

How does a production planner differ from a project manager?

The main difference between a production planner and a project manager is that a project manager is usually the person who plans and organizes the entire project, whereas a production planner is mainly involved in the planning stage of the project.

Statistics

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to Use the Just In Time Method in Production

Just-intime (JIT), a method used to lower costs and improve efficiency in business processes, is called just-in-time. It's a way to ensure that you get the right resources at just the right time. This means you only pay what you use. Frederick Taylor was the first to coin this term. He developed it while working as a foreman during the early 1900s. He observed how workers were paid overtime if there were delays in their work. He decided to ensure workers have enough time to do their jobs before starting work to improve productivity.

JIT is about planning ahead. You should have all the necessary resources ready to go so that you don’t waste money. You should also look at the entire project from start to finish and make sure that you have sufficient resources available to deal with any problems that arise during the course of your project. You will have the resources and people to solve any problems you anticipate. This way you won't be spending more on things that aren’t really needed.

There are many JIT methods.

-

Demand-driven JIT: You order the parts and materials you need for your project every other day. This will let you track the amount of material left over after you've used it. This will allow you to calculate how long it will take to make more.

-

Inventory-based: You stock materials in advance to make your projects easier. This allows for you to anticipate how much you can sell.

-

Project-driven: This approach involves setting aside sufficient funds to cover your project's costs. Once you have an idea of how much material you will need, you can purchase the necessary materials.

-

Resource-based: This is the most common form of JIT. You assign certain resources based off demand. You will, for example, assign more staff to deal with large orders. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based is an alternative to cost-based. Instead of looking at the total cost in the company, this method focuses on the average amount of raw materials that you consume.

-

Time-based JIT: This is another variant of resource-based JIT. Instead of focusing solely on the amount each employee costs, focus on how long it takes for the project to be completed.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of looking at the labor costs and time it takes to make a product, think about its quality.

-

Value-based JIT : This is the newest type of JIT. You don't worry about whether the products work or if they meet customer expectations. Instead, you focus on the added value that you provide to your market.

-

Stock-based: This stock-based method focuses on the actual quantity of products being made at any given time. It is used when production goals are met while inventory is kept to a minimum.

-

Just-in-time (JIT) planning: This is a combination of JIT and supply chain management. This refers to the scheduling of the delivery of components as soon after they are ordered. It's important as it reduces leadtimes and increases throughput.