The job of an industrial engineer is to create and implement processes that reduce wastefulness and maximize resource use. These engineers are employed in many industries to create processes that will benefit their clients in many ways. To make the company more efficient, they examine production schedules and design specifications. In order to make the company more profitable, industrial engineers must also analyse the efficiency of production processes. They also help in improving the overall quality of products and services.

Industrial engineer job requirements

The role of an Industrial Engineer is crucial in a manufacturing organisation. This person uses innovative design methods to create efficient operations for the natural or organic food industries. This individual develops innovative solutions for internal customers and manages dynamic projects to improve the manufacturing process. You must be able perform all the necessary tasks satisfactorily to qualify for this job. Industrial engineers need to be familiarized with AutoCAD/Pro-E. They also need to be conversant in advanced product quality planning techniques and the approval process.

Industrial Engineers work on optimizing efficiency through the design and testing of integrated systems. The job involves not only designing and testing integrated systems, but also studying human factors in order to optimize product quality. Other responsibilities include logistics and cost analysis as well as guest coordination. In addition, this person must be proficient in advanced technical skills such as Microsoft Office. It is necessary to have experience in manufacturing, logistics and systems design. Technical skills are essential to be able to do your job in Orlando.

Industrial engineers earn a salary

The salaries in Orlando are a good place to start if you're thinking about a career as an Industrial & Manufacturing Engineer. Orlando has a $80,325 average annual salary, making it one of the most desirable places to live. This is 6% less than the national average and 9% below the New York, NY average. Orlando's salary range is $64,260 to $96,390. The middle 67% earn $85,000 annually, while the top 10% earn $102,000.

Salaries for Industrial Engineers in Orlando can range from $89,700 USD to $114,300 USD. Industrial engineers can earn a variety of salaries, just like other careers. The above salary figures represent the average income for an Industrial Engineer who has five to ten-years of experience. However, the average salary for an Industrial Engineer with five to ten years of experience is almost double that of someone with less experience. Different industrial engineers have different pay scales.

Responsibilities of industrial engineer

This position will allow you to determine the best process design and implement strategies to improve your processes. You will have to devise and implement efficient, flexible and effective processes to meet customer requirements and achieve business goals. You will be responsible for a wide range of tasks including process improvement, capacity planning and reporting. You will also be expected to carry out time studies and observations and assist with the development of cross-functional improvement efforts.

This job requires you to have excellent communication skills and experience as an engineer, as well a solid understanding of statistical analysis. Managers will be closely involved in the development of design standards for industrial engineers and leading moderately difficult projects. They will use data analysis to create statistical reports that can improve process flow, time and quality. They will coordinate key studies, produce key metric reports, and process documentation.

FAQ

What does it take for a logistics enterprise to succeed?

You need to have a lot of knowledge and skills to manage a successful logistic business. You must have good communication skills to interact effectively with your clients and suppliers. You will need to know how to interpret data and draw conclusions. You will need to be able handle pressure well and work in stressful situations. In order to innovate and create new ways to improve efficiency, creativity is essential. You need to have strong leadership qualities to motivate team members and direct them towards achieving organizational goals.

To meet tight deadlines, you must also be efficient and organized.

What are the products of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They cover all aspects of transportation, such as packing, loading, transporting and unloading.

Logisticians ensure that products reach the right destination at the right moment and under safe conditions. They provide information on demand forecasts as well stock levels, production schedules and availability of raw material.

They can also track shipments in transit and monitor quality standards.

What skills are required to be a production manager?

Production planners must be flexible, organized, and able handle multiple tasks. It is also important to be able communicate with colleagues and clients.

What's the difference between Production Planning & Scheduling?

Production Planning (PP) refers to the process of determining how much production is needed at any given moment. Forecasting and identifying production capacity are two key elements to this process.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

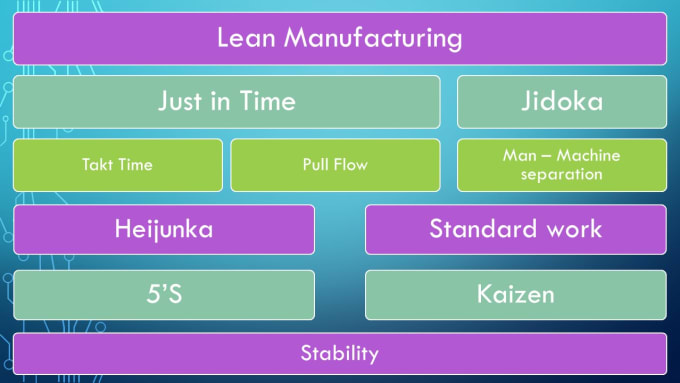

5S stands for "Sort", 'Set In Order", 'Standardize', & Separate>. Toyota Motor Corporation developed the 5S method in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

The basic idea behind this method is to standardize production processes, so they become repeatable, measurable, and predictable. This means that tasks such as cleaning, sorting, storing, packing, and labeling are performed daily. Workers can be more productive by knowing what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step has a different action and leads to higher efficiency. Sorting things makes it easier to find them later. When you arrange items, you place them together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Labeling your containers will ensure that everything is correctly labeled.

This process requires employees to think critically about how they do their job. Employees need to understand the reasons they do certain jobs and determine if there is a better way. They must learn new skills and techniques in order to implement the 5S system.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. They are more motivated to achieve higher efficiency levels as they start to see improvement.