The United States is experiencing a boom in manufacturing. The country is now the third-largest manufacturer in the world. In Q1 2018, the country's total manufacturing output surpassed $1.95 trillion. It is expected to surpass that mark by 2022. This is due in large part to automation and productivity gains.

Institutes of High Wage America

High-wage, high-paying jobs are part of the High Wage America initiative. Low wages, high levels of inequality and slow recovery from Great Recession continue to plague the American economy. But there are solutions to this current low-wage crisis. By developing an agenda for high-wage jobs, states and local stakeholders can work to improve the current conditions of the American workforce.

The first step is to develop a sustainable manufacturing approach. A plan must be developed to combat wage stagnation, poor working conditions and lack of training. The United States must fight unfair trade practices to ensure that manufacturing communities flourish.

Automated manufacturing technology

Automation technologies have transformed the way that we manufacture products, there is no doubt. The automation of manufacturing has drastically reduced costs, increased profits and helped workers as well as companies. In the US, government policy is making a difference as well, by encouraging the development of new technologies. In fact, government policies are able to help businesses grow, by encouraging new technologies development, and creating employment.

In the early 1900s, the Ford Motor Company introduced the first automated manufacturing line for automobile production. This first-of-its-kind assembly line improved Ford's production. It reduced the time to assemble a car by about one-and-a-half hours from 12 hours.

Productivity growth

A number of factors point to productivity growth in manufacturing. Large gaps in productivity between the best-run companies and others across many industries indicate that productivity growth may be possible. It is crucial to have the technology and mobility available to move production from one place to another. This is also important. Productivity can be described as the sum of output and inputs. Most commonly, these are labor hours. Outputs can be measured in units produced, sales, or both.

This measure measures productivity in the most popular way: labor productivity. This measure compares output to hours worked. The labor productivity measure can be broken down into different sectors, wages, or technological advancement. Increased productivity directly impacts company profits. Employers who work more efficiently produce more output for every hour of their labor.

Impact of outsourcing

Multifaceted effects of outsourcing in the US on manufacturing are possible. Some outsourcing can be advantageous, as it allows the country's labor costs to be lower and allows them to compete with other countries. In other cases, outsourcing has the opposite effect, causing the loss of American jobs. In some cases, it can cause American jobs to be replaced by foreign workers, while in other cases, it can result in lower wages for American workers.

Outsourcing began with American companies, and was later expanded to other countries. In order to cut costs, some companies decided to eliminate all of their "core" activities. Sodexo, a company that provides food service, IBM and UPS, were some of these companies. Foxconn, which makes computers, started outsourcing. Some companies, like Apple, outsource all of their manufacturing.

FAQ

Are there any Manufacturing Processes that we should know before we can learn about Logistics?

No. It doesn't matter if you don't know anything about manufacturing before you learn about logistics. It is important to know about the manufacturing processes in order to understand how logistics works.

What does manufacturing industry mean?

Manufacturing Industries is a group of businesses that produce goods for sale. Consumers are those who purchase these products. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. These companies produce goods using raw materials and other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

How can efficiency in manufacturing be improved?

The first step is to identify the most important factors affecting production time. The next step is to identify the most important factors that affect production time. You can start by identifying the most important factors that impact production time. Once you've identified them all, find solutions to each one.

What is the responsibility of a production planner?

A production planner ensures all aspects of the project are delivered on time, within budget, and within scope. They ensure that the product or service is of high quality and meets client requirements.

What is the responsibility of a logistics manager?

Logistics managers ensure that goods arrive on time and are unharmed. This is done by using his/her experience and knowledge of the company's products. He/she should ensure that sufficient stock is available in order to meet customer demand.

What are the requirements to start a logistics business?

To run a successful logistics company, you need a lot knowledge and skills. For clients and suppliers to be successful, you need to have excellent communication skills. You will need to know how to interpret data and draw conclusions. You will need to be able handle pressure well and work in stressful situations. To increase efficiency and creativity, you need to be creative. Strong leadership qualities are essential to motivate your team and help them achieve their organizational goals.

You should also be organized and efficient to meet tight deadlines.

What is the distinction between Production Planning or Scheduling?

Production Planning (PP), or production planning, is the process by which you determine what products are needed at any given time. Forecasting and identifying production capacity are two key elements to this process.

Scheduling refers to the process of allocating specific dates to tasks in order that they can be completed within a specified timeframe.

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

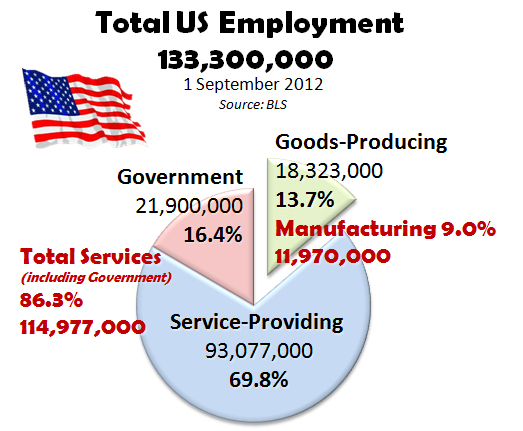

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use the 5S to Increase Productivity In Manufacturing

5S stands as "Sort", Set In Order", Standardize", Separate" and "Store". Toyota Motor Corporation invented the 5S strategy in 1954. This methodology helps companies improve their work environment to increase efficiency.

The idea behind standardizing production processes is to make them repeatable and measurable. Cleaning, sorting and packing are all done daily. Workers can be more productive by knowing what to expect.

There are five steps to implementing 5S, including Sort, Set In Order, Standardize, Separate and Store. Each step requires a different action, which increases efficiency. If you sort items, it makes them easier to find later. When you arrange items, you place them together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Finally, label all containers correctly.

This process requires employees to think critically about how they do their job. Employees must be able to see why they do what they do and find a way to achieve them without having to rely on their old methods. To be successful in the 5S system, employees will need to acquire new skills and techniques.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. They will feel motivated to strive for higher levels of efficiency once they start to see results.