The business world is an ever-evolving process. Organizations must continually improve to stay competitive. There are many ways that a business can improve its operations, from productivity to communication and operations.

Operational excellence is a management technique that seeks to improve all aspects of a business's operations. This includes reducing waste, improving processes and developing efficient workflows to boost efficiency and profitability.

The term operational excellence derives from the management theory known as scientific management. This theory was created in the 18th century, and was heavily influenced Adam Smith and Frederick Winslow Taylor. It is a process that takes years to implement and requires a lot of trial and error, but it is worth the effort.

What is Operational Excellence (Operational Excellence)?

The Institute for Operational Excellence defines operational excellence as the ability of an organization to monitor information and product flow. The ability to track product flow is essential for everyone in the organization, including senior executives and plant workers.

A culture change is required to create a culture of excellence in operations. It takes time to develop trust between employees. It involves changing leadership styles and behaviors, but this is an important first step.

What is Operational Excellence Staff's Role?

Staff responsible for operational excellence are those who implement the organization's strategy. They have a variety of responsibilities, including overseeing processes improvement events, taking part in cross-functional projects, monitoring and defining performance metrics as well as fostering culture.

They can also lead projects using methodologies for improvement such as Six Sigma, Kaizen and other similar methods. These methods have the potential to be extremely effective in improving efficiency. But they require highly trained staff in areas like project management and business analytics.

How to Create a Plan of Operational Excellence

An operational excellence strategy should be based on a method that helps you achieve your objectives as quickly as possible. This is true, in particular, if your goal is to reduce waste or improve workflows and customer service.

Tracking progress is also possible using different KPIs. These KPIs should be in line with your goals and achievable, to encourage your employees to continue striving for excellence.

These tools will help to make your operation as efficient as it can be. These tools allow you get feedback directly from your frontline employees so you can improve.

How to measure your operational excellence goals

The majority of Directors of Operations measure a combination of operational and financial numbers at the highest level along with common sense qualitative data from employee surveys and client feedback. This will give them an accurate picture of where they stand and how close they come to achieving their targets.

As operational excellence impacts every part of a business, it's crucial that each individual member has a target. The Director of Operations, for example, should have a target profit based on what they spend in people. The project manager, however, should have a target based around the billable and nonbillable aspects of their work. In this way, operational excellence at all levels can be measured, ensuring costs and revenue are in balance.

FAQ

Why is logistics important in manufacturing

Logistics is an integral part of every business. They help you achieve great results by helping you manage all aspects of product flow, from raw materials to finished goods.

Logistics play an important role in reducing costs as well as increasing efficiency.

Can we automate some parts of manufacturing?

Yes! Since ancient times, automation has been in existence. The Egyptians invent the wheel thousands of year ago. Today, robots assist in the assembly of lines.

In fact, there are several applications of robotics in manufacturing today. These include:

-

Automation line robots

-

Robot welding

-

Robot painting

-

Robotics inspection

-

Robots that create products

Manufacturing could also benefit from automation in other ways. 3D printing, for example, allows us to create custom products without waiting for them to be made.

What are the logistics products?

Logistics is the process of moving goods from one point to another.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. They help companies manage their supply chain efficiency by providing information on demand forecasts, stock levels, production schedules, and availability of raw materials.

They monitor shipments in transit, ensure quality standards, manage inventories, replenish orders, coordinate with suppliers and other vendors, and offer support services for sales, marketing, and customer service.

How can manufacturing excess production be decreased?

Better inventory management is key to reducing excess production. This would decrease the time that is spent on inefficient activities like purchasing, storing, or maintaining excess stock. This would allow us to use our resources for more productive tasks.

A Kanban system is one way to achieve this. A Kanban board, a visual display to show the progress of work, is called a Kanban board. Work items are moved through various states to reach their destination in a Kanban system. Each state represents an individual priority level.

For instance, when work moves from one stage to another, the current task is complete enough to be moved to the next stage. But if a task remains in the beginning stages it will stay that way until it reaches its end.

This keeps work moving and ensures no work is lost. A Kanban board allows managers to monitor how much work is being completed at any given moment. This information allows managers to adjust their workflow based off real-time data.

Lean manufacturing, another method to control inventory levels, is also an option. Lean manufacturing emphasizes eliminating waste in all phases of production. Anything that does nothing to add value to a product is waste. The following are examples of common waste types:

-

Overproduction

-

Inventory

-

Unnecessary packaging

-

Exceed materials

These ideas can help manufacturers improve efficiency and reduce costs.

What is manufacturing and logistics?

Manufacturing is the act of producing goods from raw materials using machines and processes. Logistics encompasses the management of all aspects associated with supply chain activities such as procurement, production planning, distribution and inventory control. It also includes customer service. As a broad term, manufacturing and logistics often refer to both the creation and delivery of products.

Why automate your warehouse

Modern warehousing has seen automation take center stage. With the rise of ecommerce, there is a greater demand for faster delivery times as well as more efficient processes.

Warehouses must be able to quickly adapt to changing demands. Technology is essential for warehouses to be able to adapt quickly to changing needs. Automation of warehouses offers many benefits. Here are some of the reasons automation is worth your investment:

-

Increases throughput/productivity

-

Reduces errors

-

Improves accuracy

-

Safety Boosts

-

Eliminates bottlenecks

-

Companies can scale more easily

-

Workers are more productive

-

It gives visibility to everything that happens inside the warehouse

-

Enhances customer experience

-

Improves employee satisfaction

-

This reduces downtime while increasing uptime

-

Ensures quality products are delivered on time

-

Eliminates human error

-

Helps ensure compliance with regulations

Statistics

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

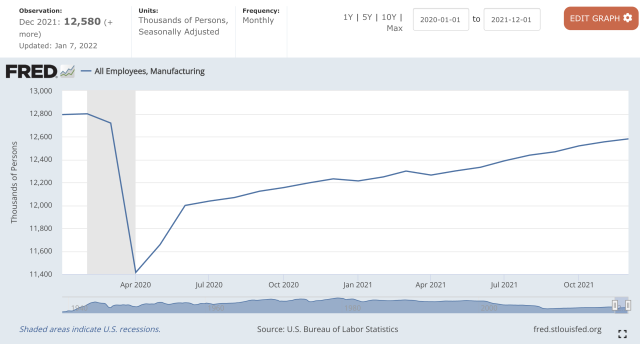

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

External Links

How To

How to use the Just-In Time Method in Production

Just-intime (JIT), which is a method to minimize costs and maximize efficiency in business process, is one way. It's the process of obtaining the right amount and timing of resources when you need them. This means you only pay what you use. Frederick Taylor, a 1900s foreman, first coined the term. Taylor observed that overtime was paid to workers if they were late in working. He decided that workers would be more productive if they had enough time to complete their work before they started to work.

JIT teaches you to plan ahead and prepare everything so you don’t waste time. It is important to look at your entire project from beginning to end and ensure that you have enough resources to handle any issues that may arise. You'll be prepared to handle any potential problems if you know in advance. You won't have to pay more for unnecessary items.

There are many JIT methods.

-

Demand-driven JIT: This is a JIT that allows you to regularly order the parts/materials necessary for your project. This will allow to track how much material has been used up. It will also allow you to predict how long it takes to produce more.

-

Inventory-based: This type allows you to stock the materials needed for your projects ahead of time. This allows you to forecast how much you will sell.

-

Project-driven: This method allows you to set aside enough funds for your project. Knowing how much money you have available will help you purchase the correct amount of materials.

-

Resource-based JIT : This is probably the most popular type of JIT. You allocate resources based on the demand. You might assign more people to help with orders if there are many. If you don't have many orders, you'll assign fewer people to handle the workload.

-

Cost-based: This is the same as resource-based except that you don't care how many people there are but how much each one of them costs.

-

Price-based: This approach is very similar to the cost-based method except that you don't look at individual workers costs but the total cost of the company.

-

Material-based: This is quite similar to cost-based, but instead of looking at the total cost of the company, you're concerned with how much raw materials you spend on average.

-

Time-based: Another variation of resource-based JIT. Instead of worrying about how much each worker costs, you can focus on how long the project takes.

-

Quality-based JIT - This is another form of resource-based JIT. Instead of thinking about how much each employee costs or how long it takes to manufacture something, you think about how good the quality of your product is.

-

Value-based JIT: This is the latest form of JIT. In this instance, you are not concerned about the product's performance or meeting customer expectations. Instead, you are focused on adding value to the marketplace.

-

Stock-based: This inventory-based approach focuses on how many items are being produced at any one time. This is used to increase production and minimize inventory.

-

Just-in-time planning (JIT): This is a combination JIT and supply-chain management. It is the process that schedules the delivery of components within a short time of their order. It's important because it reduces lead times and increases throughput.