Chemical manufacturing is a major US industry. It transforms organic or inorganic materials into useful products. It supplies raw materials to industries such as plastics and explosives. Chemical industry also faces many problems. A large number of workers are at risk of health and safety issues.

Chemical manufacturing is organized into two main segments: commodity chemicals and specialty chemicals. These two main segments share common infrastructure, utilities, as well as production processes. The products however, are very different. Specialty chemicals have typically been created for specific uses. Some of the most expensive chemicals are manufactured by specialty manufacturers. Many of these chemicals are protected by patents.

While some chemicals may be manufactured in one location only, many petrochemicals are produced in large-scale facilities. For example, large-scale chemical plants are located in Texas, Louisiana, and Rotterdam in the Netherlands. Large-scale chemical plants often share utilities, infrastructures, and create economies of scale.

The United States ranks second behind China as the largest chemical manufacturer. According to Statista, the chemical industry is worth more than $4 trillion annually. About half of industry revenue is generated by the top 50 US companies.

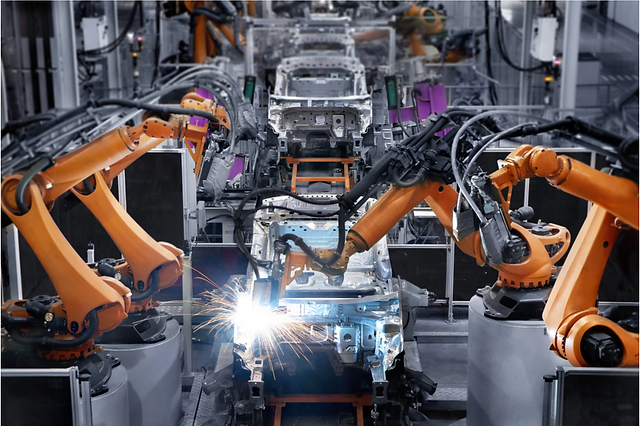

Globally, there are around 20 million chemical manufacturing workers. While most of these workers are in large-scale facilities, a small number are part-time or contract employees. The sector's employment is being affected by technological advances and increased competition.

The U.S. economic overall drives the demand of chemicals. Moreover, the chemical industry is a highly regulated sector. Governing bodies set regulations and standards for the manufacturing process. Companies need to implement sustainable manufacturing practices. Some chemicals manufacturing raw materials are extremely dangerous to extract.

The industry faces difficult procurement challenges. It is also very expensive to obtain raw materials. Companies are moving their operations to areas with lower overhead in an effort to reduce costs. Finally, some companies merge or shift production to developing nations. This will result in the elimination of jobs.

In 2008, 80 percent of jobs were in the basic chemical manufacturing section. This group is composed of manufacturers of pesticides, dyes, and other materials. Pfizer, Dow, and BASF are the most prominent manufacturers in this segment. DuPont and Formosa Plastics are also major players.

Large-scale production facilities usually have clean water. Workers are required to wear safety goggles and work in a temperature-controlled environment. However, some workers may be replaced by more sophisticated machines that can control the temperature. They work mostly night shifts.

It is possible that chemical manufacturing plants will need to adapt to new production methods. New processes could improve accuracy and reduce labor cost. The use of nanotechnology can also improve the efficiency of chemical manufacturing. Nanotechnology can also be used to reduce waste and energy consumption.

The industry's employment is also affected by technological advancements and increased foreign competition. The industry's job prospects are for a decline of 13 percent over the next four year.

FAQ

What are the responsibilities of a manufacturing manager

A manufacturing manager must make sure that all manufacturing processes run smoothly and effectively. They should be aware of any issues within the company and respond accordingly.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They should be up to date on the latest trends and be able apply this knowledge to increase productivity and efficiency.

How can manufacturing overproduction be reduced?

Improved inventory management is the key to reducing overproduction. This would reduce the time spent on unproductive activities like purchasing, storing and maintaining excess stock. This would allow us to use our resources for more productive tasks.

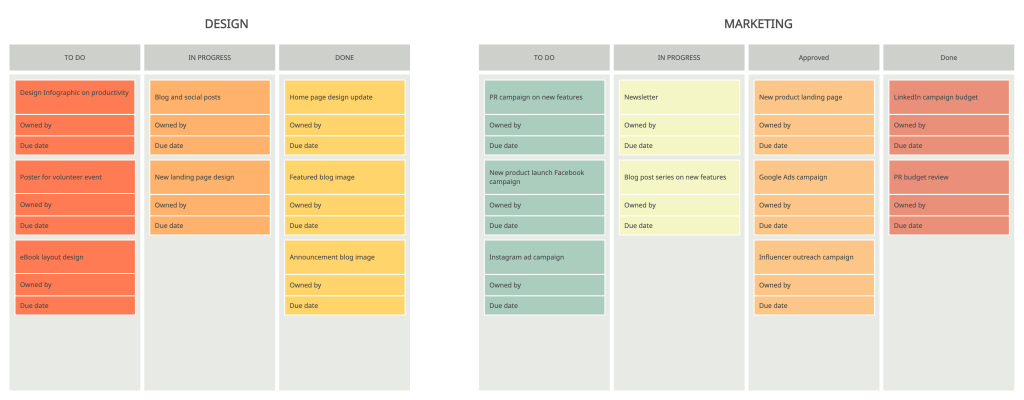

You can do this by adopting a Kanban method. A Kanban board, a visual display to show the progress of work, is called a Kanban board. In a Kanban system, work items move through a sequence of states until they reach their final destination. Each state represents a different priority.

When work is completed, it can be transferred to the next stage. However, if a task is still at the beginning stages, it will remain so until it reaches the end of the process.

This allows work to move forward and ensures that no work is missed. Managers can view the Kanban board to see how much work they have done. This information allows managers to adjust their workflow based off real-time data.

Lean manufacturing can also be used to reduce inventory levels. Lean manufacturing focuses on eliminating waste throughout the entire production chain. Anything that does nothing to add value to a product is waste. Here are some examples of common types.

-

Overproduction

-

Inventory

-

Packaging not required

-

Overstock materials

Manufacturers can reduce their costs and improve their efficiency by using these ideas.

What is production management?

Production Planning refers to the development of a plan for every aspect of production. This document is designed to make sure everything is ready for when you're ready to shoot. It should also contain information on achieving the best results on set. This includes shooting schedules, locations, cast lists, crew details, and equipment requirements.

The first step in filming is to define what you want. You might have an idea of where you want to film, or you may have specific locations or sets in mind. Once you've identified the locations and scenes you want to use, you can begin to plan what elements you need for each scene. For example, you might decide that you need a car but don't know exactly what model you want. If this is the case, you might start searching online for car models and then narrow your options by selecting from different makes.

After you've found the perfect car, it's time to start thinking about adding extras. What about additional seating? Or perhaps you need someone walking around the back of the car? Maybe you want to change the interior color from black to white? These questions will help guide you in determining the ideal look and feel for your car. You can also think about the type of shots you want to get. Are you going to be shooting close-ups? Or wide angles? Maybe the engine or steering wheel is what you are looking to film. These things will help you to identify the car that you are looking for.

Once you have established all the details, you can create a schedule. You can use a schedule to determine when and where you need it to be shot. You will need to know when you have to be there, what time you have to leave and when your return home. This way, everyone knows what they need to do and when. Hire extra staff by booking them ahead of time. You should not hire anyone who doesn't show up because of your inaction.

It is important to calculate the amount of filming days when you are creating your schedule. Some projects only take one or two days, while others may last weeks. While creating your schedule, it is important to remember whether you will require more than one shot per day. Multiplying takes in the same area will result both in increased costs and a longer time. You can't be certain if you will need multiple takes so it is better not to shoot too many.

Budget setting is another important aspect in production planning. You will be able to manage your resources if you have a realistic budget. It is possible to reduce the budget at any time if you experience unexpected problems. But, don't underestimate how much money you'll spend. You will end up spending less money if you underestimate the cost of something.

Planning production is a tedious process. Once you have a good understanding of how everything works together, planning future projects becomes easy.

How can manufacturing avoid production bottlenecks

Production bottlenecks can be avoided by ensuring that processes are running smoothly during the entire production process, starting with the receipt of an order and ending when the product ships.

This includes both planning for capacity and quality control.

Continuous improvement techniques such Six Sigma can help you achieve this.

Six Sigma Management System is a method to increase quality and reduce waste throughout your organization.

It is focused on creating consistency and eliminating variation in your work.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- According to the United Nations Industrial Development Organization (UNIDO), China is the top manufacturer worldwide by 2019 output, producing 28.7% of the total global manufacturing output, followed by the United States, Japan, Germany, and India.[52][53] (en.wikipedia.org)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

External Links

How To

How to Use Lean Manufacturing for the Production of Goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the original book on lean manufacturing, "The Machine That Changed the World," in 1990.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It emphasizes the elimination of defects and waste throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing is widely used in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five principles are the basis of lean manufacturing:

-

Define Value- Identify the added value your company brings to society. What makes you stand out from your competitors?

-

Reduce waste - Stop any activity that isn't adding value to the supply chains.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize and Simplify – Make processes as consistent, repeatable, and as simple as possible.

-

Build Relationships- Develop personal relationships with both internal as well as external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses have adopted lean production techniques to make them more competitive. According to some economists, lean manufacturing could be a significant factor in the economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

You can apply Lean Manufacturing to virtually any aspect of your organization. Lean manufacturing is most useful in the production sector of an organisation because it ensures that each step in the value-chain is efficient and productive.

There are three main types in lean manufacturing

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT is a process in which components can be assembled at the point they are needed, instead of being made ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing: ZDM ensures that no defective units leave the manufacturing plant. Repairing a part that is damaged during assembly should be done, not scrapping. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement: Continuous Improvement aims to improve efficiency by continually identifying problems and making adjustments to eliminate or minimize waste. Continuous improvement involves continuous improvement of processes and people as well as tools.